News Details

28

2018

-

06

"Galvanized polyurethane pipe insulation knowledge to discuss the topic 』3

The development of the heating industry has promoted the progress of various types of products.

The development of the heating industry has promoted the progress of various types of products. With the complexity and diversification of use spaces, pipe corridors and overhead environments, the demand for open-air use of insulation pipes continues to increase, and traditional underground insulation pipes Due to the poor UV resistance of PE outer protection, it is not suitable for use in open air environments. Therefore, galvanized overhead insulation pipes with galvanized steel sheets as outer protection have been more widely used.

This product uses galvanized steel sheets through a pipe rolling machine to make galvanized pipes instead of PE outer protective pipes. It uses the characteristics of galvanized steel sheets such as corrosion resistance, oxidation resistance, and ultraviolet radiation resistance, and combines galvanized protective pipes with polyurethane insulation layers and inner workings. The steel pipe has the advantage of being one-piece and adapts to the requirements of open-air use. It also has the irreplaceable advantages of PE outer protection type and galvanized white iron insulation pipe after insulation.

However, the use of galvanized steel sheets is not without corrosion or other risks. At the same time, in view of the complexity of galvanized steel sheets in terms of grades, quality, standards, etc., in-depth research on galvanized steel sheets is also required, and then scientific and standardized management is carried out.

Compared with the traditional buried PE outer protection insulation pipe, the main difference of this product is the galvanized steel plate for the outer protective layer. The selection of galvanized steel plate is the core of this product, but there is currently not much research on this issue in the industry. There are many confusions in use, so the focus of this article is to put forward some pertinent opinions on the use of galvanized steel sheets.

6. The grade of galvanized steel plate will directly affect the protective effect

● A brief introduction to the basic information of steel grades and grades

There are many types of steel grades and grades, and they often have corresponding grades depending on the industry and conditions of use. Different brands have different usage directions and requirements, which require careful study and careful use. The following selects relevant grades from "GB-T/2518" for a brief introduction, as shown in the figure.

A brief introduction to some brands of "GB-T/2518"

Brand explanation: such as DX51D+Z, DX51D+ZF

D: means galvanized

X: Indicates that there are no requirements for substrate processing methods

51: Indicates steel grade number

Z: represents pure zinc coating

ZF: indicates zinc-iron alloy coating

● Specifications for the use of steel grades and grades

As can be seen from the above table:

(1) National standards have relatively broad requirements for ingredients, but in the actual production process, the impact of ingredients is very direct and requires in-depth study.

(2) Different grades have greatly different properties. By carefully comparing the properties, you can find the decreasing yield strength trend. Therefore, from the perspective of performance alone, some of the above grades cannot be used in the production of overhead pipes. Therefore, it is necessary to evaluate the performance. Do in-depth research.

(3) From the perspective of the entire above-mentioned grade series and the application of each type of grade above, the key lies in forming. It must have sufficient processability. This is the characteristic of this grade series. Note that easy forming is for the galvanized pipe coiling process. Advantageous, but it does not necessarily have the guarantee of resistance to impact, pressure, and cracking.

(4) From the perspective of steel base materials, the above-mentioned steel types used are all low-carbon steel or higher quality steel types. Some of the steel types must be produced using interstitial-free steel (IF steel). This type of steel type is difficult to produce and the price is high. High, generally used in the automotive industry.

(5) ZF-zinc-iron alloy coating is a heat treatment of the coating based on general galvanizing. It is generally used in the automotive industry. For processing in this area, there is little practical significance in making the outer protection of the overhead passenger aircraft.

In summary, if you choose a brand based on the above, more in-depth research is required. The applicability of DX52D-DX57D is questionable, and the ingredients, performance and processing details cannot be ignored.

We suggest that considering the anti-corrosion and protective effects of the overhead pipe outer protection, its strength should not be too low, and it should have both machinability and reduce unnecessary cost waste. You can consider choosing the structure of the SSXXX (SS350) series. Grade galvanized sheet is used, and its performance is specifically required, that is, the yield strength is between 240-400MPa.

7. Pay attention to the potential risks to the quality of galvanized steel plate products

● The significance of quality control of galvanized steel plate products

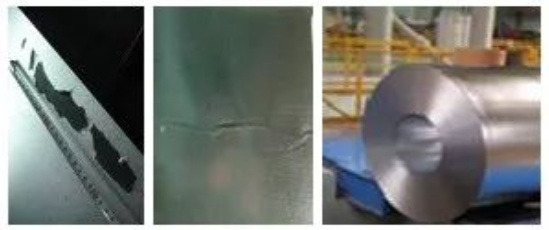

There are also many quality problems in the production process of galvanized steel sheets, such as plate shape problems, uneven zinc layer thickness, dezincification, friction black spots, white rust, passivation spots, missing plating, etc. If these problems are not solved quickly Failure to control or detect during use will have subsequent adverse effects and more serious hidden dangers. Therefore it is necessary to carry out strict quality control and management. Some defects of galvanized steel sheets are shown in the figure.

Picture of some defects of galvanized steel plate

●

Galvanized steel sheets are made into outer protective steel pipes by a pipe rolling machine. During this process, problems such as corrosion, missing plating, scratches, and flat shapes of the raw materials cannot be reduced or eliminated, so strict control is required.

We recommend that the surface quality of galvanized steel sheets for the production of galvanized overhead pipes should be better than the FB surface requirements, with no white rust, no missing plating, no serious scratches, and plate shape problems such as surface damage that affects corrosion resistance and processing. Defects such as chromatic aberration and stains are difficult to detect visually. It is recommended that both manufacturers and insulation pipe companies need to strictly control from a quality perspective.

8. Summary of the topic

To sum up, we have conducted relatively in-depth research and production practice on galvanized overhead pipes. Based on the current use and management of the industry, our company believes that the standardized and scientific management of this product is an issue that should be fully paid attention to in the industry. . Regarding the core issue, that is, the selection and control of galvanized steel sheets, we have also reached the following views and opinions:

(1) The corrosion of galvanized steel sheets cannot be ignored. The corrosion process of the zinc layer needs to be considered, and the zinc layer thickness control and surface processing must be carried out in a targeted manner.

(2) During the design or actual application process, special attention should be paid to the weight of the zinc layer, and scientific selection standards and requirements should be formed, that is, to ensure that the function of the insulation pipe is not affected, and to consider the aesthetic requirements of its overhead use.

(3) During the selection and design process of galvanized steel sheets, sufficient attention should be paid to the consideration of surface treatment, and quality control of the passivation process should be carried out in a targeted manner.

(4) The impact of different spangle states of galvanized steel sheets on the anti-corrosion ability must be clearly understood and studied.

(5) Combine the standard selection of required galvanized steel sheets with design requirements. Be sure to use appropriate standards or stricter requirements for galvanized steel sheet selection and product quality.

(6) Considering the anti-corrosion and protective effects of the outer protection of the overhead pipe, its strength should not be too low. At the same time, it must have both machinability and reduce unnecessary cost waste.

(7) The surface quality of galvanized steel sheets for the production of galvanized overhead pipes must be better than the FB surface requirements, and quality defects must be strictly controlled. Both galvanized steel sheet manufacturers and insulation pipe companies need to carry out more stringent control from a quality perspective.

The above is some experience and understanding of our company in the production and research process. Due to the limited level, the discussion is not in-depth enough, and there are inevitable omissions. Criticisms and corrections are welcome. I also sincerely hope that this article can serve as a starting point, promote the standardization of industry management, and the standardization of products and technologies, and be beneficial to interested viewers. Due to the length of the article and the inconvenience of in-depth development, I have some unfinished words and hope that fellow readers can have more in-depth exchanges.