News Details

13

2018

-

06

"Galvanized polyurethane pipe insulation knowledge to discuss the topic 』2

The development of the heating industry has promoted the progress of various types of products.

The development of the heating industry has promoted the progress of various types of products. With the complexity and diversification of use spaces, pipe corridors and overhead environments, the demand for open-air use of insulation pipes continues to increase, and traditional underground insulation pipes Due to the poor UV resistance of PE outer protection, it is not suitable for use in open air environments. Therefore, galvanized overhead insulation pipes with galvanized steel sheets as outer protection have been more widely used.

This product uses galvanized steel sheets through a pipe rolling machine to make galvanized pipes instead of PE outer protective pipes. It uses the characteristics of galvanized steel sheets such as corrosion resistance, oxidation resistance, and ultraviolet radiation resistance, and combines galvanized protective pipes with polyurethane insulation layers and inner workings. The steel pipe has the advantage of being one-piece and adapts to the requirements of open-air use. It also has the irreplaceable advantages of PE outer protection type and galvanized white iron insulation pipe after insulation.

However, the use of galvanized steel sheets is not without corrosion or other risks. At the same time, in view of the complexity of galvanized steel sheets in terms of grades, quality, standards, etc., in-depth research on galvanized steel sheets is also required, and then scientific and standardized management is carried out.

Compared with the traditional buried PE outer protection insulation pipe, the main difference of this product is the galvanized steel plate for the outer protective layer. The selection of galvanized steel plate is the core of this product, but there is currently not much research on this issue in the industry. There are many confusions in use, so the focus of this article is to put forward some pertinent opinions on the use of galvanized steel sheets.

3. Attention should be paid to the surface treatment of galvanized steel sheets

●The significance of surface treatment of galvanized steel sheets

The chemical properties of zinc are also relatively active and are prone to "white rust" corrosion. Therefore, galvanized sheets generally have post-treatment processes after processing, mainly surface passivation. Its function is to form a chromate film on the surface of the galvanized layer. Its corrosion resistance is better. According to different environmental protection requirements, there are environmentally friendly trivalent chromic acid passivation and non-environmental friendly hexavalent chromic acid passivation. Although this chemical conversion film is very thin, it improves the protective ability of the zinc layer in the salt spray test by 7-10 times. It can also change the appearance color during the passivation process according to the needs. It is also one of the ways to beautify and customize it.

● Relevant requirements for surface condition treatment

Passivating the surface can effectively protect the zinc layer from corrosion. During the production process of overhead pipes, the selection of passivated galvanized steel sheets should be considered. At the same time, the process control of the passivation process and the chromium point content of the passivation layer must also be controlled in a targeted manner to avoid shoddy products during the passivation process. In terms of passivation type selection, environmentally friendly trivalent chromic acid passivation can be considered, and due to cost considerations, hexavalent chromic acid passivation with stronger corrosion resistance can be selected.

We suggest that during the selection and design process of galvanized steel plates, sufficient attention should be paid to the consideration of surface treatment, and targeted quality control of the passivation process should be carried out.

4. The impact of the spangle state of galvanized steel sheets on the quality must be clear

● The significance of the spangle status of galvanized steel sheets

Zinc splatter is a distinctive appearance feature unique to hot-dip galvanized steel sheets. It is caused by the growth of dendrites when the liquid zinc layer solidifies. It is generally affected by alloy elements such as Pb, Sb, and Bi. Pure zinc plating baths will not produce zinc. The zinc flower layer varies according to the state of the zinc flower. From the perspective of the size and shape of zinc flowers, they can be divided into three types: large zinc flowers, small zinc flowers and no zinc flowers. As shown in the picture.

Large spangle. Different spangle surface morphology. No spangle.

● Key points for selecting the spangle status of galvanized steel sheets

All three types of zinc flowers can play a relatively good anti-corrosion role. Among them, no zinc flowers are better and large zinc flowers are worse. However, large zinc flowers are relatively more advantageous from an aesthetic point of view and require targeted trade-offs.

From the perspective of production technology and quality stability, it should be relatively more suitable to use zinc-free galvanized sheets, but the price is generally higher.

We suggest that since it does not have a direct impact on the protective effect, it is not necessary to be too rigid in a certain form. However, the impact of the spangle state of galvanized steel sheets on the anti-corrosion ability must be clear and cannot be generalized.

5. The quality differences between different galvanized steel plate standards are quite different and need to be paid attention to.

● Different standards for galvanized steel sheets

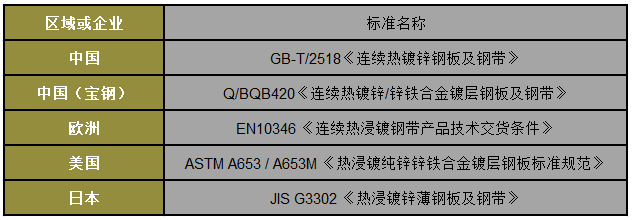

Domestic steel companies generally produce galvanized steel sheets using foreign and Chinese national standards. The main standards used are shown in the table below.

Related standards for galvanized steel sheets

These standards have similarities. It should be said that the reasonable selection of galvanized steel plates that strictly comply with the above standards for use in the external protection of overhead pipes can ensure the protection and corrosion resistance requirements.

●Different standards have different adaptability

From the perspective of product quality control and production process control of domestic steel companies, due to standard descriptions and related parameters and subtle changes, galvanized steel sheet products using different standards will be treated differently. This will lead to large differences in product quality and applicability, so selection needs to be targeted based on the use needs.

We suggest that the standard selection of required galvanized steel sheets should be made based on the design requirements, and galvanized steel sheets constrained and controlled by the above standards or more stringent standards must be used.

There are eight parts in total, to be continued. If you are interested in the content of this part and want to have in-depth understanding or communication, please contact our company through the official account or phone!