News Details

19

2017

-

08

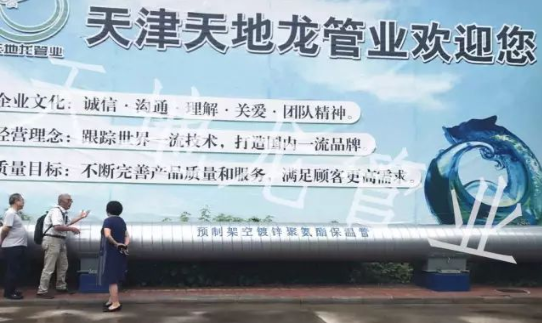

"Seminar on Resistance Reduction in Long-distance Pipeline Insulation Pipes" was successfully held in Tiandilongg Pipe Industry on August 19, 2017

After careful preparation by the North China Design and Research Institute of China Municipal Engineering, the Seminar on Resistance Reduction in Insulated Pipes for Long Distance Pipelines was successfully held on August 19, 2017 in our company.

After careful preparation by the North China Design and Research Institute of China Municipal Engineering, the Seminar on Resistance Reduction in Insulated Pipes for Long Distance Pipelines was successfully held on August 19, 2017 in our company.The meeting invited a number of experts, including Liao Rongping, Wang Huai, Yang Liangzhong, Jiang Jianzhi of North China Design and Research Institute of China Municipal Engineering; Yang Jian of Urban Construction Research Institute; Bai Dongjun of the Fourth Inspection Institute of Quality of Construction Engineering in Beijing; and Yu Ning of Dalian Xinguang Pipeline Manufacturing Company Limited, etc. The meeting focused on the reduction of friction resistance in the operation process of long distance pipelines to enhance the effectiveness of energy and reduce the operating costs and other factors, and was held from the theory ofSupport, coating research and development, coating performance testing, coating aging test program and other aspects of in-depth discussions, and gave constructive suggestions for the heating product development, testing and production of a new direction, put forward higher requirements.

With the national energy saving and environmental protection policy requirements, in recent years the heat industry long-distance pipeline project more and more, due to the commonly used working steel pipe for Q235B material, the inner wall itself is rough, friction resistance in the medium transportation process is larger, and with the use of longer time, the inner wall corrosion is serious, the resistance increases year by year, increasing the loss of energy, and invariably increase the pipeline operating costs.Our company from the end of 2014 began to research and development of various types of anticorrosive drag reduction coating performance characteristics, and various types of coatings for a number of conventional tests and cold and heat exchange performance experiments, and ultimately the trial production of successful thermal insulation pipe with internal drag reduction coatings, in order to verify the effectiveness of the drag reduction, in August 2016, our own design and installation of a simulation of the heat supply of 80 ℃ hot water, the supply back to the length of 200 meters of the two sets of coated and uncoated pipeline to carry out comparativetest.In the pipe diameter, water supply pressure, flow rate under the same conditions, test records the supply and return water supply and uncoated pipe flow and pressure drop data, calculated by the data comparison, intuitively two sets of pipeline pressure difference rate of 25% or more, the drag reduction effect is obvious.

On the day of the meeting, the experts surveyed the experimental pipeline of our company on the spot, gave affirmation and put forward valuable suggestions for improvement.We also hope that through the discussion and guidance of this meeting, we can make our new product "internal resistance-reducing insulation pipe" performance more excellent and widely used, enhance the environmental protection and energy saving effect in the process of hot water insulation and transmission, and contribute to the progress of the industry and the social welfare of Tiandilongg.

Previous Page