News Details

18

2017

-

05

2017 Heating Engineering Construction and College Operations Seminar Successfully Concluded

May 13, 2017 a two-day heating engineering construction and efficient operation of the seminar came to a successful conclusion, since 2014, China Municipal Engineering North China Design and Research Institute

May 13, 2017 a two-day heating engineering construction and efficient operation of the seminar came to a successful conclusion, since 2014, China Municipal Engineering North China Design and Research Institute, "Gas and Heat" magazine began to organize the first session, since then the number of participants in the annual session of the heating conference year by year, this year it is nearly 500 enthusiastic participation, the entire venue is full of enthusiasm, full house.To date, four consecutive heating seminars, almost become our annual heat industry event, from the design and research institutes, well-known experts at home and abroad, the provinces and cities of heating companies, to the relevant equipment, raw materials, production and suppliers, every year, through such a large-scale seminar, mutual exchange of management experience, the promotion of energy saving, environmental protection, efficiency technology, improve the level of heat operation and management, to achieve energy saving and emission reduction.

Thank you very much for China Municipal Engineering North China Design and Research Institute, "Gas and Heat" magazine can give us "heat people" every year to provide such a reunion opportunity, so that we have technical exchanges with each other at the same time but also enhance each other's feelings; thank you for all the leaders, experts can take time out of their busy schedules for us to carry out a variety of thematic speeches!Thanks to all the leaders and experts who can spare time from their busy schedules to give us speeches on various topics to guide us to new ideas and broaden new horizons; we also cherish this gathering with our friends from all walks of life in the same industry, and hope that we can share our experiences and make progress together, and contribute to the development of the industry and environmental protection in our own small way.

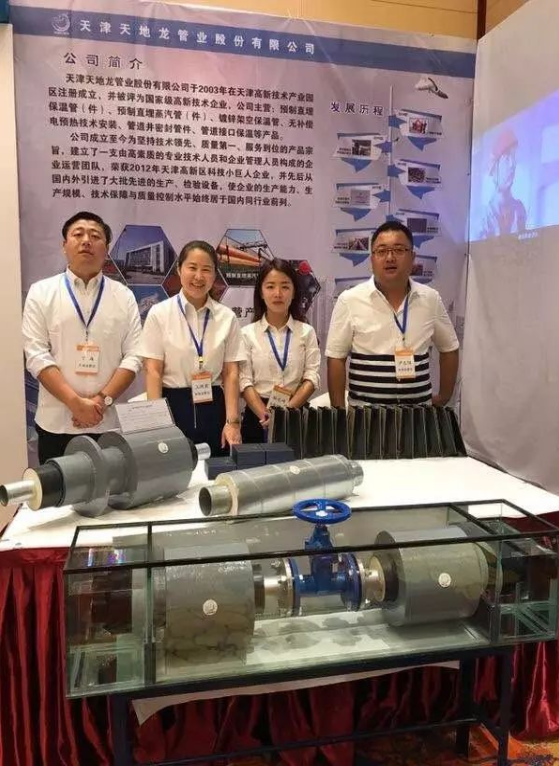

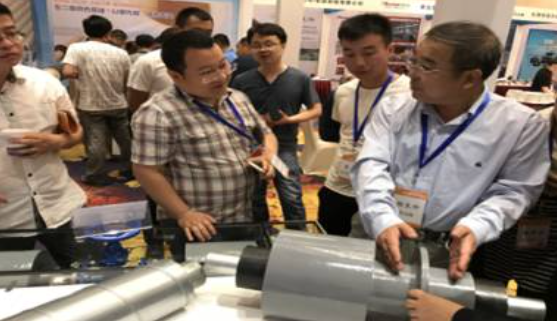

Tiandilongg pipe industry since its inception has been committed to research and development, production of efficient, energy-saving, safe and environmentally friendly prefabricated direct burial thermal insulation hot water pipe (pieces), steam pipe (pieces), electric preheating construction, in order to keep up with the advanced technology and development trends in the industry, we continue to research and development, innovation, and have obtained 23 national patents, since the first session of the heating conference began to be held in 2014, we have been actively participating in the conference every year, this year as an exhibitionThis year, as an exhibitor, we take this opportunity to show you our new technology and new products - overhead galvanized polyurethane insulation pipe and new flexible sealing over-wall casing.During the meeting, the new products attracted a lot of users' attention, and they had on-site consultation and communication with us.

New flexible sealing over-wall casing, the structure of the flexible connection with the pipeline and casing sealing connection, the formation of a sealed cavity, the success of the isolation of the fluid through the casing and the pipeline between the path.Sealing structure for the new flexible, elastic state, compared with the general flexible structure, its stability is higher not only to ensure the waterproof sealing of the pipeline through the wall, but also to compensate for the axial expansion and contraction of the insulation pipeline, the product has been verified by the customer's on-site use, and completely solved the pipeline leakage problems that have plagued the industry for many years in the well room.

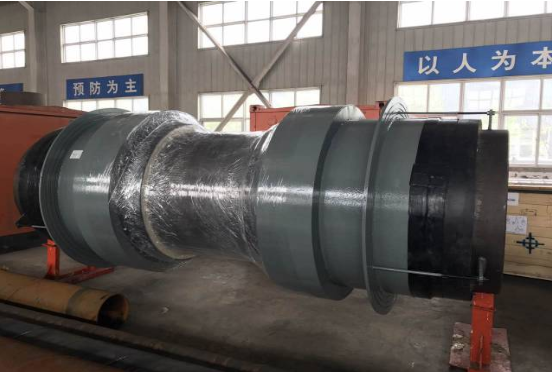

Overhead galvanized polyurethane insulation pipe, mainly used for overhead pipelines and comprehensive pipeline corridor project, compared with the traditional FRP overhead pipeline or inorganic thermal insulation material + white iron hand-coated process;

Its advantages are obvious:

First, the three-in-one structure, so that its thermal insulation performance is better, heat loss is extremely low, long-term operation can save a lot of energy, significantly reduce energy costs, while extending the service life of the pipeline.

Second, the current overhead pipeline (oil or steam), most of its process is the first inorganic material insulation after manual wrapping of galvanized iron, its fit is poor, especially the traditional inorganic insulation cotton process, insulation cotton is easy to deformation, collapse, the appearance of the poor, with the new process of overhead galvanized polyurethane insulation pipe, the galvanized outer tube using mechanical equipment for one-time molding, not only to ensure that the sealing effect of the rolled pipe, its appearance is also moreBeautiful and beautiful.

Third, the material cost advantage, the use of galvanized steel instead of PE pipe, material, galvanized steel price than PE pipe preferential 50% -70%.Material dosage advantage, because PE pipe needs to be under a certain thickness in order to achieve the required protective performance, especially the large pipe diameter dosage, and galvanized steel itself, such as hardness, mechanical strength and other advantages so that it does not need to be thicker to achieve the same protective effect.Process advantages, PE extrusion processing method, through the melting, molding, cooling, power consumption, low production efficiency, while galvanized coiled pipe only need to have been done to bend the steel plate into a circle can be, low energy consumption, high efficiency.

Next Page