Products -

Prefabricated Steam Insulation Fixed Section

Key words:

Prefabricated Steam Insulation Fixed Section

Related downloads :

MATERIALOF STEELPIPE

Generally, the material is 20# steel, and the standard is GB/T8163-2018 seamless steel pipe.According to CJJ/T104-2014 standard, if the medium temperature ≤ 300 ℃, can choose the material for Q235B, standard GB/T9711 and GB/T3091 spiral steel pipe.

THERMALINSULATION MATERIAL

Prefabricated directly buried steam insulation pipe insulation materials used are: aerogel felt, centrifugal glass wool, water-repellent composite silicate, aluminum silicate felt.

● Aerogel felt features: ultra-low thermal conductivity, reduce heat loss, reduce product caliber, reduce costs, light weight, small size.

● Centrifugal glass wool features: moderate temperature resistance, low thermal conductivity, moderate cost, good resistance to boiling.

● Characteristics of microporous calcium silicate: high temperature resistance, high cost, stable moisturizing performance, high density.

● Characteristics of aluminum silicate: non-combustible, high temperature resistance, moderate cost, high density, poor boiling resistance.

ANTI-CORROSION OF EXTERNALPIPE

● Main features of FRP anti-corrosion: polyester, epoxy resin or phenolic resin is used as the main raw material.Light weight, smooth surface, high strength, high hardness, impact resistance, temperature resistance of 90℃~100℃, strong electric insulation, acid and alkali salt corrosion resistance, easy on-site patching process, short curing time and relatively low cost.

The main features of three PE anti-corrosion: the bottom layer is fusion bonded epoxy, the middle layer is adhesive, and the surface layer is extruded polyethylene.It has good mechanical strength and impact toughness, water resistance, acid and alkali salt resistance and bacterial corrosion, temperature resistance of 70℃~80℃, cold state (room temperature) strength is relatively large.The cost is high, the coating process is complicated, the site patch, the anti-corrosion of the shaped pipe fittings is difficult to match with the pipe body.

● The main characteristics of polyurea coating: it is a solvent-free, non-polluting anticorrosion material with good tensile strength, elongation, flexibility, abrasion resistance, aging resistance and corrosion resistance.Good thermal stability, can be used for a long time at 120 ℃, withstand 150 ℃ short-term thermal shock.

● The main characteristics of 100% solids solvent-free polyurethane: strong adhesion, resistance to water vapor erosion, long service life, and increasingly widespread applications.

UTER SLIDING STRUCTURE

The structure of the insulation layer and the outer tube because there is a layer of air between the air layer, the pipeline in the transportation and construction process of invasive water can be discharged in the process of gradual warming, and is therefore more suitable for the rainfall, the water table in high areas.However, for the soil with high content of chlorine ions, sulfur ions, etc. (especially in coastal areas), the corrosion protection of the outer steel pipe is further strengthened.

The outer sliding structure is designed based on the idea of "steel gutter", which can make full use of the elbow for natural compensation, reducing the cost, and at the same time reducing the thrust of the fixed pier.The pipeline can be divided into a number of relatively independent parts at the fixed pier, between the two fixed piers to set up the drainage pipe (preferably two sets), then the drainage pipe can not only eliminate moisture gas, but also as a daily operation of the signal pipe, you can monitor the operation of the pipe network at any time.

INNER SLIDING STRUCTURE

Inside sliding due to the use of excellent thermal insulation performance of organic insulation materials, such as polyurethane, thermal insulation effect is good, the outer surface temperature is lower.The inner sliding structure of the steel outer pipe, in addition to good insulation, but also has high strength, good sealing performance, not easy to enter a large amount of water, but the structure is expensive.

PRODUCT INTRODUCTION

The design of the steam fixed support should be able to withstand the friction of the working pipe, the internal pressure imbalance force of the pipe, the compensator's blind force (with the effective area of the compensator) and so on the role of the combined force.

Our company cooperates with domestic famous design institutes to produce national patented product (an insulated internal fixed bearing), which can realize the insulation and isolation between internal and external steel pipes.

STRUCTURALCOMPOSITION

Consisting of a working steel pipe, an outer steel pipe, a flange casing, an insulating material, a flange 1, an annular steel plate and a ribbed plate, for a fixed support for the transmission of steam for heat supply in towns and cities.

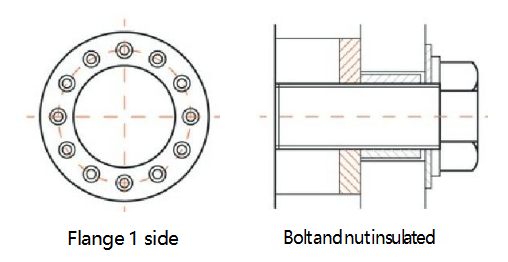

Flange 1 consists of a set of flanges with a plurality of bolts and nuts as shown below

One end of the flange 1 is welded to the flange casing, the other end is welded to the inner wall of the outer protection steel pipe, the bolts, nuts and flanges in contact with the part of the gasket of high-temperature-resistant insulating material (orange part in the figure), bolts are located in the middle of the two flanges part of the insulating sheath.

The other end of the flange sleeve is connected to the working steel pipe by an annular steel plate with reinforcing ribs. When the working steel pipe is subjected to pipeline thrust, these loads can be transferred to the pipeline structure to limit the pipeline displacement and to withstand the pipeline thrust.

Insulation materials such as aerogel felt, glass wool, aluminum silicate felt, etc. are wrapped between the working pipe and the outer protection pipe.

STRUCTURALFEATURES

A flange casing is added to the traditional steam fixed section to insulate the working pipe from the outer pipe, reducing heat transfer and improving cathodic protection of steam piping.

Prefabricated Directly Buried Steam Insulation Pipe and Fittings Specifications | |||

Norm | Working Tubes | Outer galvanized pipe | Insulation thickness |

(mm) | Outer diameter*Wall thickness(mm) | Outer diameter*Wall thickness(mm) | (mm) |

89/273 | 89*4.5 | 273*6.0 | 70 |

108/273 | 108*4.5 | 273*6.0 | 65 |

133/325 | 133*4.5 | 325*7.0 | 80 |

159/377 | 159*5.0 | 377*7.0 | 85 |

219/478 | 219*7.0 | 478*8.0 | 100 |

273/529 | 273*7.0 | 529*9.0 | 105 |

325/630 | 325*8.0 | 630*10.0 | 125 |

377/720 | 377*8.0 | 720*10.0 | 140 |

426/820 | 426*9.0 | 820*10.0 | 140 |

478/820 | 478*9.0 | 820*10.0 | 140 |

529/920 | 529*9.0 | 920*10.0 | 165 |

630/1020 | 630*10.0 | 1020*11.0 | 165 |

720/1120 | 720*12.0 | 1120*12.0 | 170 |

820/1220 | 820*12.0 | 1220*13.0 | 170 |

Previous Page

Next Page

Previous Page

Next Page

Related Product

Prefabricated Directly Buried Hot Water Insulation Pipe

Prefabricated insulation elbow

Prefabricated insulation across three

Consult Now

If you are interested in our products, please leave your email, we will contact you as soon as possible, thank you!